Ferrous Metals and Non-Ferrous Metals

Quick links

- What is the difference between ferrous and non-ferrous metals?

- Where does the word ferrous come from?

- Why does it matter if a metal is ferrous or not?

- What is a ferrous metal?

- Why isn’t every metal containing iron ferrous?

- What are the qualities of ferrous metals?

- How is ferrous metal used?

- What is a non-ferrous metal?

- What are the qualities of non-ferrous metals?

- How are non-ferrous metals used?

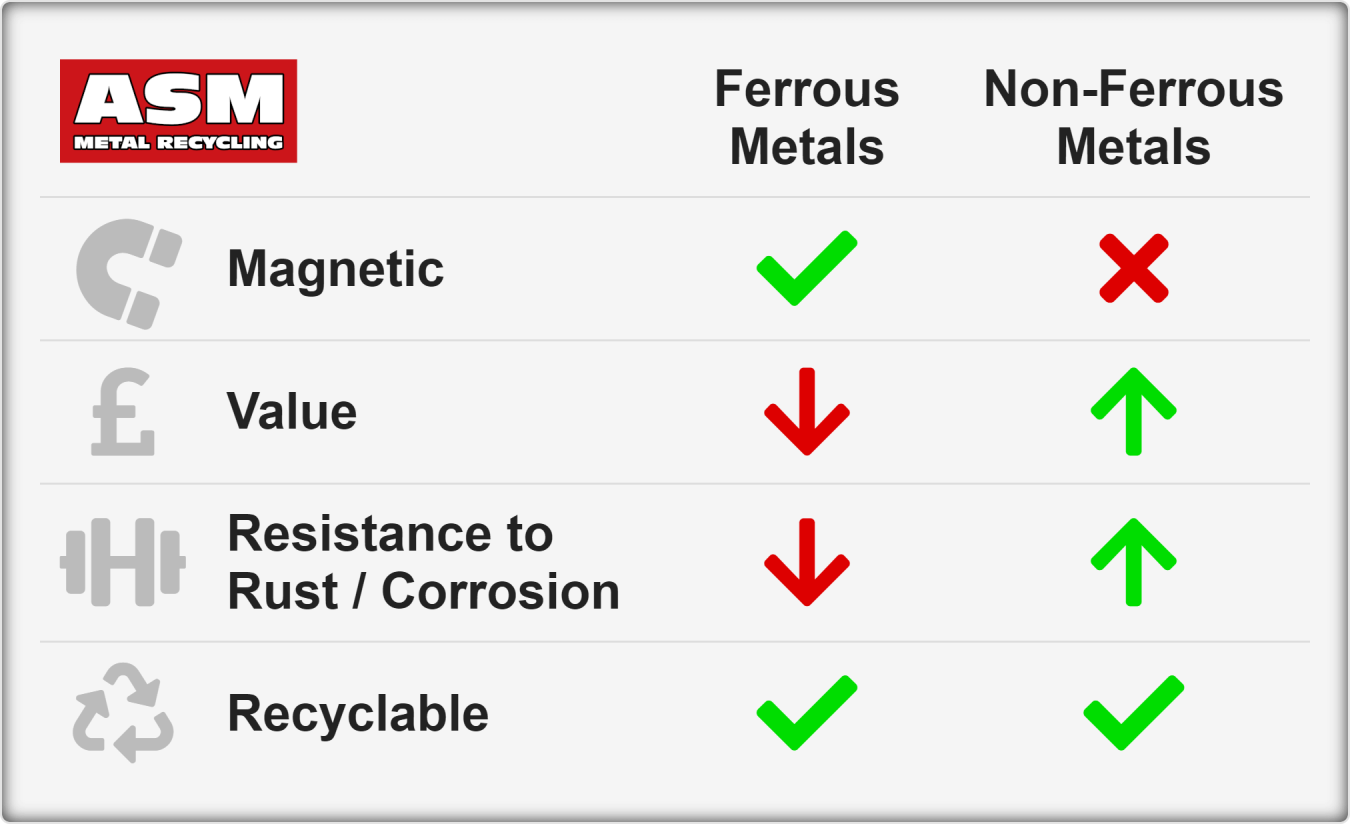

What is the difference between ferrous and non-ferrous metals?

Put simply, ferrous metals contain iron and non-ferrous metals do not. Non-ferrous metals are rarer, more valuable and resistant to corrosion than ferrous metals. Ferrous and non-ferrous metals can both be recycled. Magnetising the iron in ferrous metals can separate ferrous and non-ferrous materials.

Where does the word ferrous come from?

The word ferrous derives from the Latin word ‘ferrum’, which means iron (chemically known as Fe). Non-ferrous simply means no iron or only tiny amounts are found in the metal.

Why does it matter if a metal is ferrous or not?

What any metal is made of is vital to deciding how it might be used. While ferrous metals are renowned for their strength and ductility, the presence of iron makes them vulnerable to rusting when exposed to air and moisture, so certain uses for them will be limited by these characteristics.

What is a ferrous metal?

Ferrous metal means that it has iron in its make-up. But this doesn’t mean just traces or small amounts of iron. When the term ferrous metal is used, it typically means that iron is a large percentage of the metal’s elemental composition. In fact, it’s likely to be the second or third largest part of the metal, if not the largest.

Why isn’t every metal containing iron ferrous?

Many metals contain small amounts of iron. If they were all classed as ferrous, the category wouldn’t have much meaning, so a small amount is not considered enough to declare the metal ferrous.

What are the qualities of ferrous metals?

The iron found in ferrous metals tends to make them magnetic, strong, and hard. The characteristics of a ferrous metal can differ greatly depending on the other elements they are made up of. Because they have a high carbon content, ferrous metals are vulnerable to rust when exposed to moisture.

How is ferrous metal used?

Because ferrous metals tend to be strong and durable, they have many uses in construction and engineering. You can find ferrous metals in large structures such as skyscrapers and bridges. Furthermore, ferrous metals are used in shipping containers, industrial piping, cars, railroad tracks, and domestic tools.

Below are some types of ferrous metal examples and their uses:

Cast Iron

Composition

Has more carbon than most other types. relatively affordable due to lack of other alloying elements outside of iron and carbon.

Uses

Cookware, small components subject to wear such as gears, rods, and pins, and mining equipment.

Carbon Steel

Composition

Typically over 90% iron and the most commonly used ferrous metal.

Uses

Structures, furniture, and automotive components.

Composition

100% recyclable Usually have a high amount of chromium that helps resist corrosion better than carbon steels.

Uses

Appliances, pharmaceutical and medical equipment, food-grade equipment, and knives.

Engineering Steel

Composition

Mostly iron, but amounts of copper, vanadium, tungsten, manganese, and other elements can tailor it for toughness, ductility, tensile strength, hardness, and other properties.

Uses

Tools, dies, and machining equipment.

What is a non-ferrous metal?

Non-ferrous metals do not contain a significant amount of iron in their composition. Non-ferrous alloys generally have iron compositions of less than 1% as measured by weight.

What are the qualities of non-ferrous metals?

It is hard to define the common properties of non-ferrous metals because there is such a variety of metals that fall into the non-ferrous category. However, non-ferrous metals all do have a couple of things in common: They are not magnetic, and they do not rust (although they can corrode). This means that non-ferrous metals will never form the red flaky material you see on some steel and iron, because rust is iron oxide and non-ferrous alloys have no significant amount of iron in them.

How are non-ferrous metals used?

Non-ferrous metals have had many uses throughout history, with copper and bronze being heralded for advancing civilisation through from the stone age to 1700 BCE, when people learnt to mine copper and tin to make bronze weapons. Today, non-ferrous metals are used for construction, making tools, electrical cables, vehicle engines, pipelines, containers, and even cutlery.

Here are some details on the more common non-ferrous metal examples, but there are many more such as tungsten, titanium, zinc, silver, gold, platinum, and lead.

Composition

Without the addition of alloying elements, it is more ductile and not quite as strong as many steels (and far lighter) but can still achieve very high strengths. It forms a protective oxide layer that helps it reduce the risk of corrosion.

Uses

Marine equipment, aerospace equipment, construction material such as beams and rails, and certain types of cookware.

Composition

In an unalloyed state it is softer, more ductile, and not as strong as carbon steel. Copper can be alloyed with other elements to give it improved mechanical properties. When copper is alloyed with tin it is bronze and when alloyed with significant amounts of zinc, it is brass.

Uses

Electrical components such as wires, terminals, and other types of connectors, coating on some currency, pipes for plumbing, tools, and decorative work.

Nickel

Composition

Nickel is another popular non-ferrous alloy. Nickel is known for its toughness, ability to perform in high temperature and low temperature environments, and corrosion resistance. Nickel is not often used in its pure form, and like copper and aluminium, it is often alloyed with other elements to gain superior chemical and mechanical properties.

Uses

Cryogenic equipment such as tanks; hot-section aerospace equipment such as combustion chamber components; and marine equipment.

Composition

Brass is copper alloyed with a lot of zinc. Adding aluminium improves resistance to corrosion, manganese, iron, tin and aluminium its durability, and lead its machinability. Brass has high thermal and electrical conductivity.

Uses

Taps, locks, piping, letter boxes. ornaments and many electrical appliances.

Get in touch with us about ferrous and non-ferrous metal

If you still have any question about ferrous and non-ferrous metals, you can get in touch by emailing us at info at asm-recycling dot co dot uk, or give us a call on 01296 33 77 11. We can provide up to date information on prices and advice for dealing with ferrous and non-ferrous metals.